Additive manufacturing of metal alloys yields great potential for the aerospace industry (and others) as it allows the generation of geometrically complex structures with high specific strength, low density and high corrosion resistance. For example, General Electric has demonstrated the possibility of printing titanium fuel injectors for their LEAP engine, EADS has printed a nacelle hinge bracket for the Airbus A320, Boeing incorporated more than 300 printed parts in their 777X airplane … For such critical applications, the structural quality of printed parts is of utmost importance. Small deviations in print conditions, e.g. change in laser fluence, variation in powder quality, non-uniform gas flow, build position … may result in varying print quality, and even in inferior parts containing porosity, cracks, residual stress and geometrical deviations, amongst others. Current inspection protocol involves the use of X-rays, but this is a time-and cost-inefficient method for high-volume applications.

This 3-year RESON-AM project aims at developing a fast, practical and sensitive quality control technology for AM metal parts. The project is a close collaboration between several leading industrial partners (Materialise, Siemens and MatchID) and academia (KULeuven and UGent). The project is funded by SIM-Flanders (Strategic Initiative Materials in Flanders).

UGent will specifically focus in the project on the development and implementation of robust (non)linear resonant ultrasound spectroscopy procedures, coupled to deep learning algorithms, in order to assess the structural quality of printed metal parts in a fast and reliable manner. The current postdoc vacancy concerns the implementation and realization of a flexible and sensitive measurement platform using NI-PXIe technology. Piezo-electric sensors and/or (pulsed) lasers will be employed for excitation and subsequent acquisition of vibrations in a wide frequency bandwidth of 0-500 kHz. Both linear and nonlinear vibrational test approaches are of interest. Data analysis tools will be developed in order to interpret the (non)linear vibrational response and to extract (non)linear vibrational features (e.g. resonance parameters). These features will provide crucial information on part quality, and will give insight in the physical origin(s) of print variability.

We search a mature researcher having a strong background in vibration testing & analysis, and large experience in experimental hardware and software (LabVIEW) implementation. The researcher will closely collaborate with another researcher at UGent who focuses on deep learning tasks, as well as with the researchers of the project partners.

More information can be found on

https://composites.ugent.be/PhD_job_vacancies_PhD_job_positions_composit...

The Simpleware Product Group at Synopsys are running a webinar on March 2nd on using AI solutions to lift the burden of manual CT inspections for turbine blades.

To learn more and register, please see https://attendee.gotowebinar.com/register/1099136013627123728?source=iMe...

Transportation of heavy acidic fluids is often done with specifically designed lined pipelines. The pipelines typically have an outer steel wall (thickness ~15 mm) and an inner ceramic coating (thickness ~1 mm). The proper functioning of such lined pipelines is almost exclusively determined by the inner ceramic coating. In case there would be a leak in the ceramic coating, the acidic fluid will corrode through the outer steel wall in a matter of hours, leading to a full shutdown of the industrial plant.

Upon installation of the lined pipelines, the ceramic coating could already have a varying quality: e.g. thickness variations, porosity clusters, varying stiffness,... Further, during the operational lifetime of the pipeline, the acidic fluid will gradually erode the ceramic coating (~0.05 mm/year). Hence, it is crucial to properly assess the actual state of the inner ceramic coating at certain time intervals. Current inspection procedures involve a full team of operators which need to go inside the pipeline (after thorough flushing with water) for assessing the quality of the ceramic coating.

This project focusses on the development of a novel, efficient and in-situ non-destructive test method to monitor the structural integrity of lined pipelines from the outside during their operational lifetime. The ultrasonic technique of interest is the classical contact pulse-echo ultrasound (pipelines are above the ground and accessible). From the ultrasonic response, several signal parameters will be extracted and analyzed in order to estimate the quality of the ceramic coating. In order to cope with the harsh industrial circumstances, this involves the development and implementation of (i) advanced excitation signals (e.g. coded waveforms), (ii) novel signal analysis tools in time/frequency domain and (iii) inversion procedures. In a second stage, the developed method will be implemented in a phased array system with a rolling transducer. Such a system will allow to assess large parts of the lined pipeline in a time-efficient manner.

This project requires a researcher with a strong interest in instrumental hardware (NI-PXIe platform will be employed), a good background in LabVIEW, as well as a high affinity with advanced signal processing techniques. This project is funded by industry and the final developed device will be tested on-site at the facilities of the industrial partner.

Only candidates with a Master/PhD degree in Mechanical Engineering, Electrical Engineering, Civil Engineering, (Applied) Physics or similar should apply. You are interested in instrumental physics and signal processing. You have good knowledge of LabVIEW, and preferably also of MATLAB. You are interested to interact with industry and to disseminate your results and findings.

For more information, please visit:

http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_composites.html

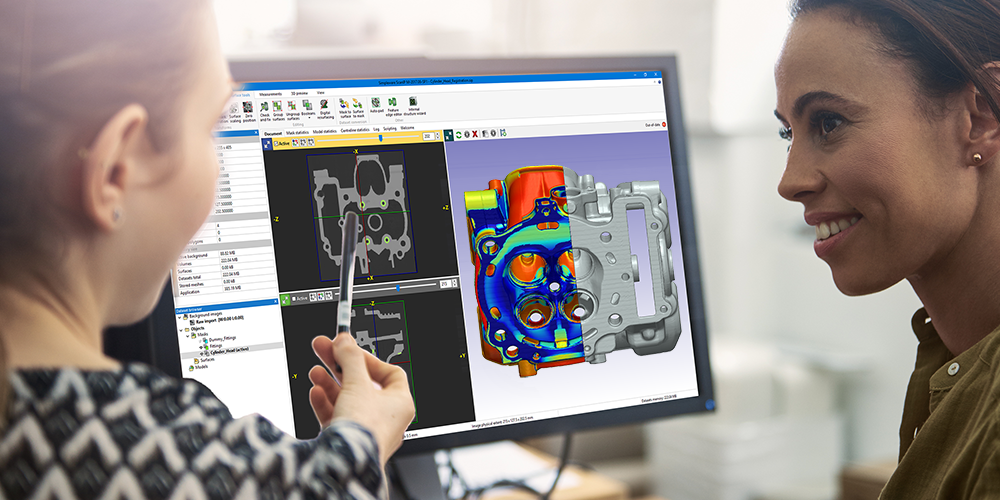

Join us for this webinar on Wednesday, May 20th, where we'll be looking at methods for identifying part defacts using Simpleware software.

We'll look at an example of working with a machined simple hole plate (usually used for CT calibration) to focus on tools useful for Non-Destructive Testing (NDT) and the production of manufactured parts. We will show automated tools for segmentation and correction, as well as surface deviation, shape fitting and measurement tools.

Learn more about how to take part in this webinar.

The Mechanics of Materials and Structures research group at Ghent University (Belgium) is recruiting 5 PhD/postdoc researchers in the field of experimental and computational mechanics of composites. There are 5 positions:

- PhD vacancy (3 years) on experimental testing of thermoplastic automotive composites

- Postdoctoral vacancy (3 years) on multi-scale thermomechanical modelling of thermoplastic composites

- PhD/postdoc vacancy (4 years) on computational mechanics of large wind turbine blades

- PhD vacancy (4 years) on nondestructive testing (NDT) of composites using Guided WavesPhD vacancy (3 years) on mechanical testing of recyclable vitrimer composites

- PhD vacancy (3 years) on mechanical testing of recyclable vitrimer composites

More information can be found on:

http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_composites.html

Join us for this interactive web workshop where we will demonstrate 3D image processing and analysis using Simpleware software. We walk also you through the workflow of building high-quality models for the inspection and non-destructive evaluation of manufactured parts.

Learn more and register here

Ghent University (Belgium) has three open PhD positions of each 4 years on ultrasound inspection of layered materials, ranging from composites over coated pipelines to wood. More information can be found on http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_compo....

The use of 3D printed metal structures is taking a very fast ramp-up in industry. General Electric has demonstrated the possibility of printing titanium fuel injectors for their LEAP engine, EADS has printed a nacelle hinge bracket for the Airbus A320, Boeing is printing plastic inlet ducts for high-altitude aircrafts, hip implants and other prosthetics are exploiting the design freedom of additive manufacturing (AM),..

Additive manufacturing of titanium alloys yields great potential for the aerospace industry (and others) as it allows the generation of geometrically complex structures with high specific strength, low density and high corrosion resistance. However the inspection of such 3D printed components is almost impossible with traditional Non-Destructive Testing (NDT) techniques because of the typical complex geometries and internal cavities. A very interesting alternative is PCRT (Process Compensated Resonance Testing), a high-frequency vibration technique that tries to detect defects by evaluating relative shifts in the resonance spectrum.

In this postdoctoral position, it is the purpose to devise and build an upgraded PCRT set-up for inspecting 3D printed metal parts with complex geometry, to implement data-acquisition and to develop advanced post-processing tools for identification of small defects in the frequency domain. You will closely collaborate with another postdoctoral research in our group, as well as with several large industries (Materialise, Siemens and Vibrant). This postdoctoral position is partially funded by SIM-Flanders (Strategic Initiative Materials in Flanders).

Only candidates with a PhD degree or equivalent experience should apply. The candidate should have a strong experimental background in vibration techniques and data analysis in frequency domain.

More information can be found on

http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_compo...

We look for 4 postdoctoral researchers (or equivalent by experience) in the field of software development for and nondestructive inspection of 3D printed components. The targeted sectors of application are medical and high-end industrial applications. Companies are strongly involved in the research projects.

More information can be found on http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_compo....

Join this webinar and see how Simpleware software adds value to the inspection and non-destructive evaluation of high-value, low-production-volume parts. Register to attend the live webinar or to watch a recording after the broadcast at your convenience.

Learn how quantitative inspection workflows are completed from industrial CT data, incorporating wall thickness analysis, dimensional measurement and surface deviation from benchmark Surface/CAD geometries. Discover the unique possibilities of Simpleware software to generate CAD geometries for design, and simulation-ready meshes to non-destructively evaluate the performance of manufactured components against design requirements.

The use of 3D printed metal structures is taking a very fast ramp-up in industry. General Electric has demonstrated the possibility of printing titanium fuel injectors for their LEAP engine, EADS has printed a nacelle hinge bracket for the Airbus A320, Boeing is printing plastic inlet ducts for high-altitude aircrafts, hip implants and other prosthetics are exploiting the design freedom of additive manufacturing (AM),...

Additive manufacturing of titanium alloys yields great potential for the aerospace industry (and others) as it allows the generation of geometrically complex structures with high specific strength, low density and high corrosion resistance.

However the inspection of such 3D printed components is almost impossible with traditional Non-Destructive Testing (NDT) techniques because of the typical complex geometries and internal cavities. A very interesting alternative is PCRT (Process Compensated Resonance Testing), a high-frequency vibration technique that tries to detect defects by isolating very small shifts in the resonance spectrum at very high frequencies.

In this Postdoctoral position, it is the purpose to build a PCRT set-up for inspecting 3D printed metal parts with complex geometry, to implement the data-acquisition and to develop advanced post-processing tools for identification of defects in the frequency domain. The research is in close collaboration with Materialise and Siemens, two leading companies in the development of 3D printing. The project is funded by SIM-Flanders (Strategic Initiative Materials in Flanders).

Only candidates with a PhD degree or equivalent experience should apply. The candidate should have a strong background in vibration techniques and data analysis in frequency domain.

For more information, visit http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_compo...

Dear Colleagues,

We would like to invite you to submit an abstract for the ‘ASNT Spring Symposium 2018’ under Track : NDT for Additive Manufacturing. This symposium held at Orlando, FL, USA, March 26–29, 2018.

Normal

0

false

false

false

EN-US

X-NONE

AR-SA

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:"Table Normal";

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-parent:"";

mso-padding-alt:0in 5.4pt 0in 5.4pt;

mso-para-margin-top:0in;

mso-para-margin-right:0in;

mso-para-margin-bottom:8.0pt;

mso-para-margin-left:0in;

line-height:107%;

mso-pagination:widow-orphan;

font-size:11.0pt;

font-family:"Calibri",sans-serif;

mso-ascii-font-family:Calibri;

mso-ascii-theme-font:minor-latin;

mso-hansi-font-family:Calibri;

mso-hansi-theme-font:minor-latin;

mso-bidi-font-family:Arial;

mso-bidi-theme-font:minor-bidi;}

| Attachment | Size |

|---|---|

| 972.72 KB |

We are looking for a PhD and postdoc researcher in thermographic inspection of composites, in the context of NDT (NonDestructive Testing) and defect detection.

More information can be found on http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_compo....

One PhD (4 years) and two Postdoc (3 years) vacancies are available in the composites research group at Ghent University in Belgium. The different open positions deal with nondestructive testing methods for composites inspection (vibration/thermography) and fatigue of 3D printed metals. More information can be found on http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_compo....

Non-destructive testing (NDT) refers to techniques that are used in the life-cycle of a structural component to investigate their quality, functionality and 'health' without destroying the object, nor affecting its properties. The continuous development of more advanced materials, like fiber reinforced plastics, requires new and more sophisticated NDT techniques. One such an innovative NDT technique is the Ultrasonic Polar Scan (UPS) which has recently been developed, both experimentally and numerically, in our research group. The UPS analyzes the reflected or transmitted ultrasonic signals for a wide range of azimuthal and polar angles. The recorded information (amplitude, phase, or time-of-flight) provides a fingerprint of the local material properties. The UPS method has already been successfully applied for the (visco-)elastic characterization of metals, plastics as well as unidirectional fiber reinforced plastics.

In addition, the UPS technique is also highly sensitive to different types of complex damage features, such as fiber distortion, fatigue damage, delamination, corrosion ... This 4-year project involves both experimental and numerical research, and will extend the current status of the UPS research on three levels:

- Identification of material properties (stiffness, attenuation, layering, orientation) for multilayer fiber reinforced plastics.

- Implementation of a nonlinear version of the UPS to increase its sensitivity to early-stage damage features and kissing bonds.

- Practical redesign of the current laboratory set-up to obtain an efficient inspection tool which may be used in industry.

This vacancy at Ghent University focuses more on the experimental part and less on the numerical part. Numerical support will be provided by a PhD student at KULAK-KULeuven, who will start in August 2015. In addition, further support will be given by a postdoctoral researcher at Ghent University (starts in October 2015) who will focus on the further development of the UPS technique. It is clear that you will interact closely with these 2 researchers during the project.

Only candidates with a Master degree should apply. The candidate should have a background in ultrasonics and nondestructive testing, preferably combined with knowledge of fiber reinforced plastics.

More information can be found on http://www.composites.ugent.be/PhD_job_vacancies_PhD_job_positions_compo...

Stress corrosion cracks can be a serious problem in many engineering industries, and especially so for critical parts. While an ultrasonic transducer can be used for the non-destructive evaluation of cracks with simple shapes, complex branching cracks, such as stress corrosion cracks, require ultrasonic arrays that consist of multiple transducers and are able to inspect at multiple angles.

This project involved optimising an ultrasonic array design using real stress corrosion crack shapes obtained with X-ray CT scans and a hybrid model for simulating complex ultrasonic array responses. The model combined a finite element (FE) method with simple ray tracing. Simpleware software was used to obtain the crack geometry from X-ray CT data, contributing towards an overall methodology for improving future ultrasonic NDE of cracks.

Thanks to: Department of Mechanical Engineering, University of Bristol - M.V. Felice, A. Velichko, P.D. Wildox; NDE Laboratory, Rolls-Royce plc - T. Barden, T. Dunhill

Learn more about Simpleware at http:///simpleware.com

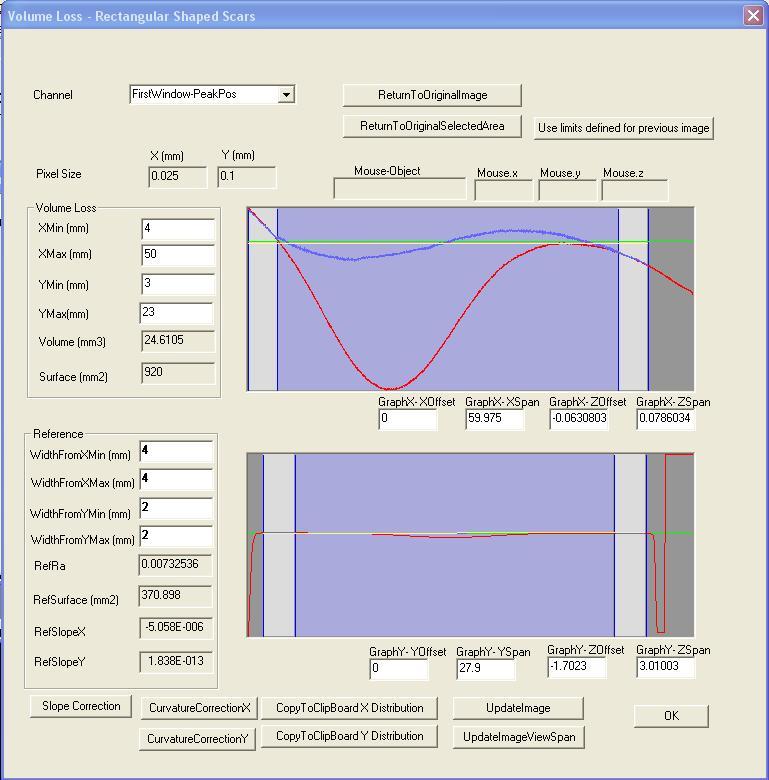

Novacam 3D Profilometer Software

The Novacam three dimensional software programs are used with all Novacam Profliometers. The program permits the consumer to define how big the region, or line to be measured, along with the lateral resolution from the measurement.

Novacam's high end Data Acquisition Profilometer Software programs are incorporated with all of MicroCam non-contact profilometers.

- PC, Windows®-based

- User-friendly interface for scan control on any Novacam profilometer inspection station

The Applying Programming Interface (API) can be obtained for system integrators and OEMs. Using the API, all kinds offline and online programs could be covered.

Data acquisition of a gear head surface

Gearhead 3-dimensional surface images

Data analysis and three dimensional imaging may occur offline or instantly.

Data output formats: point cloud, 32 bit tiff

Output exportable to:

- CAD/CAM software: PolyWorks, Geomagic, SolidWorks, Creo Elements/Professional (Professional/ENGINEER), etc.

- Imaging, visualization and statistical analysis software: ImageJ, Octave, MatLab, Mathematica, IDL, IGOR Professional

- Surface and roughness analysis software

- STL extendable

Option: Novacam Volume Loss Application

Novacam Volume Loss Application

Novacam Volume Loss Application processes the acquired surface dimensional data to find out volume loss from abrasion and put on:

- with micron precision

- on samples and aspects of various shapes and dimensions

See more about identifying volume loss .

Contact:

Novacam Technologies Inc

277 Lakeshore Road, Suite 04

Pointe Claire, QC.

H9S 4L2

http://www.novacam.com

tel: (514) 694-4002

fax: (514) 630-6420

e-mail: info@novacam.com

| Attachment | Size |

|---|---|

| 654.13 KB |

A RA (MS level) position is available in the Department of Engineering Technology, University of North Texas-Denton in the fields of characterization of piezoelectric crystals, design and modeling of piezoelectric resonators and sensors. The position will start from spring, 2012. Candidates should have a Bachelor/Master's degree in engineering mechanics, mechanical engineering or electrical engineering with good academic standing and should have some experiences in the following:

(1) Non-destructive material characterization method,

(2) Proficient in LABVIEW or MATLAB- based experiment test,

(3) Fundamental knowledge in solid mechanics,

(4) Sound knowledge in piezoelectric devices such as resonators, energy harvester, and sensors.

Candidates should already have GRE score, international candidates also should have TOEFL score.

Interested applicants should send a detailed C.V. and transcript to Prof. Zhang at harry.hfzhang@gmail.com.

The National Committee on Applied Mechanics of Engineers Australia is hosting the 6th Australasian Congress on Applied Mechanics (ACAM 6) in Perth, Australia on December 12th-15th 2010.

ACAM 6 (http://www.acam6.org/) aims to provide an international forum for researchers, industry practitioners, engineers and postgraduate scholars to promote, exchange and disseminate knowledge and experiences of the most recent results and advances in a wide range of topics in Applied Mechanics.

The program is aimed at providing opportunities for discussions and exchanges of insights and information on new ideas and problems in the area of Applied Mechanics. This will be facilitated by a number of parallel sessions of oral presentations. A number of leading international researchers are going to present keynote papers.

The congress will also include a one-day seminar hosted by the Western Australian branch of the Australian Institute for Non-Destructive Testing. Topics will include case studies and new developments in non-destructive testing.

All papers accepted for publication in the proceedings will be subject to a full peer review. Selected papers will also be published in a special issue of the Australian Journal of Mechanical Engineering.